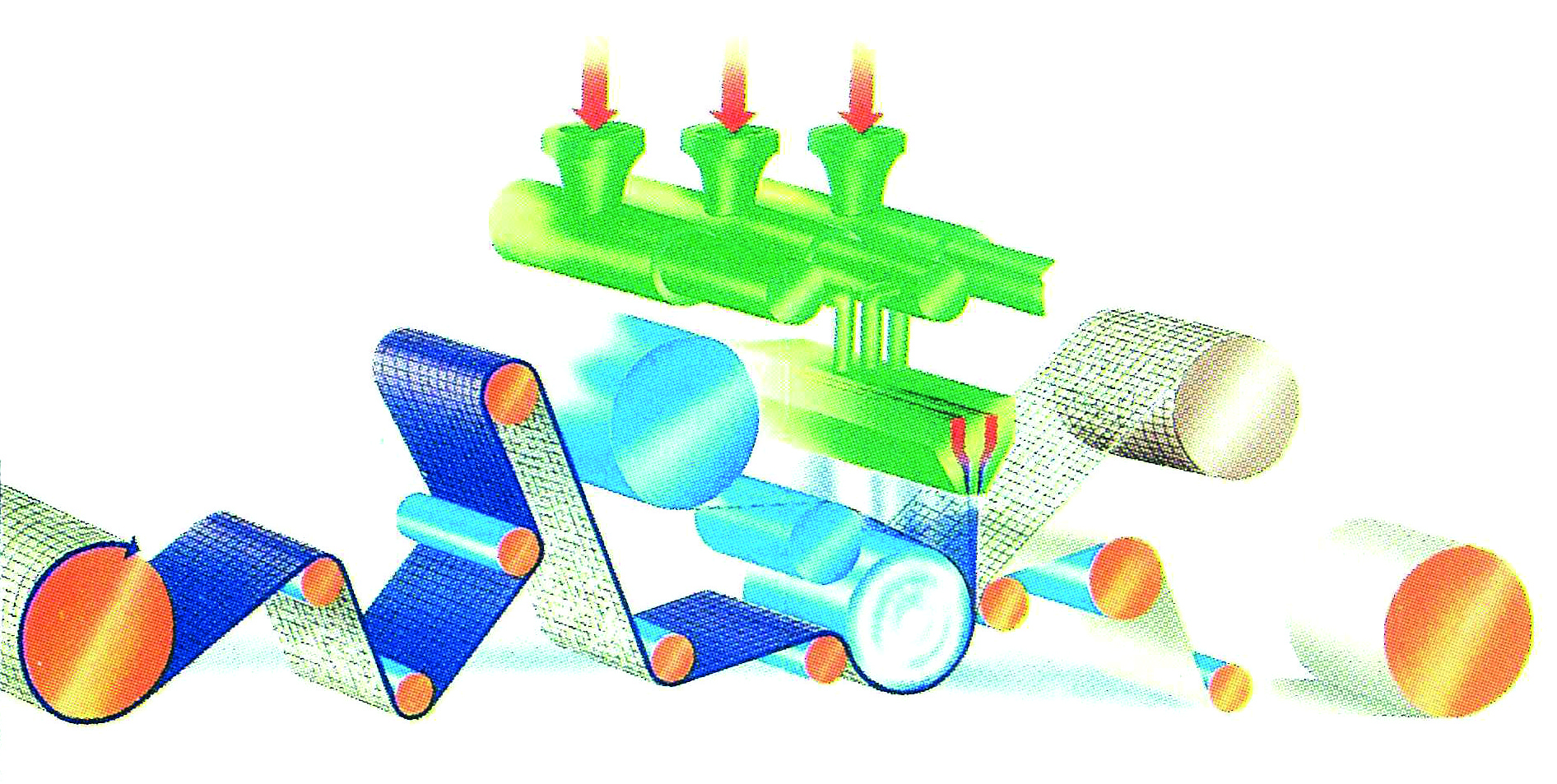

The production system is based on the extrusion process of a multilayer plastic film that is in-line

- coated to another web like paper, foil, film etc.

- laminated between two or more layers of various materials

The advantages of this process:

- high production speed

- minimal production tolerances

- highest efficiency

- ecologically beneficial

Inhalt hinzufügen

Inhalt hinzufügen

Inhalt hinzufügen

Röthel manufactures custom-designed products on 5 efficient production lines in its German production plants in Bochum and Neumünster.

- Capacity of 110.000tons or 720 mio. m²

- Triple Co-Extrusion technology

- Width up to 330cm

- Multicolour flexographic printing up to 330cm width with eco-friendly waterbased inks

- Coating from 3 up to 100g/m²

- Roll diameter up to 150cm

- Micro-perforation

- Converting of most sensitive webs

- Glossy and mat type surface coatings

- Sealable, printable and glueable coatings

- Narrow web slitting

- Computer controlled production

- On-line measuring with closed loop coating system

As specialists in coating and laminating we optimize and develop products in close cooperation with our customers.

Constant knowledge exchange with our partners ensures systematic and cost efficient product development.

Our experts are delighted to offer you every assistance in all your application needs.

Röthel manufactures tailor-made products from a wide variety of high quality raw materials. Deep market knowledge and experienced international cooperation with proven partners assure reliable logistics with high quality base products.

Substrates:

- All kind of papers

- Board

- Aluminium foils

- Polymer films (LDPE, LLDPE, HDPE, BOPP, PA, PET)

- Tissues, non wovens

- Wovens

- Scrims and fabrics

Polymers:

- PE (LD, HD)

- PP Ionomere

- EVOH

- EMMA

- EVA

- PLA

- Metallocene

- Blends

- Masterbatch